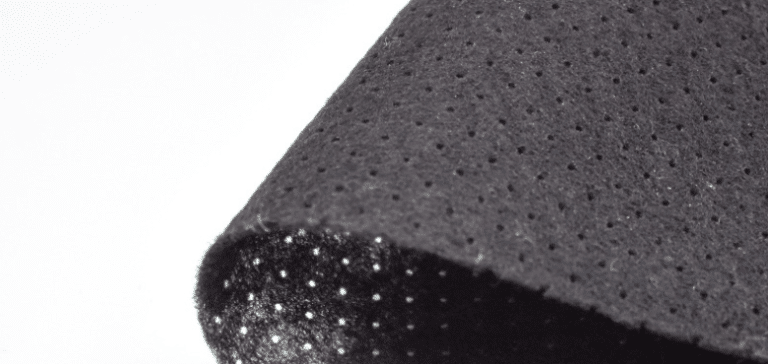

Needle punched nonwoven fabrics are a type of material produced by mechanically orienting and interlocking fibers through the use of barbed needles. The process involves repeatedly pushing barbed needles into a fiber web to entangle them into a more cohesive and stable fabric. The resulting fabric is dense, thick, and highly durable, making it suitable for a variety of applications across different industries. Here are some of the primary needle punched nonwoven fabrics uses:

Needle Punched Nonwoven Fabrics Uses in Modern Infrastructure

Needle Punched Nonwoven Fabrics Uses in Civil Engineering

The first of the many needle punched nonwoven fabrics uses is in the field of civil engineering. These fabrics serve as advanced geotextiles that enhance soil structure, control erosion, and improve drainage systems. This is crucial for the foundation of roads, landfills, and protective embankments, highlighting one of the critical needle punched nonwoven fabrics uses in supporting modern infrastructure.

Needle Punched Nonwoven Fabrics Uses in the Automotive Industry

Interior Enhancements with Needle Punched Nonwoven Fabrics

Another significant category in needle punched nonwoven fabrics uses is in automotive interiors. Employed in trunk liners, carpet backings, and insulation pads, these fabrics improve comfort, sound moderation, and temperature control inside vehicles. The durability and versatility in these needle punched nonwoven fabrics uses make them essential for enhancing passenger experiences.

Needle Punched Nonwoven Fabrics Uses in Filtration and Environmental Safety

Precision Filtration Solutions with Needle Punched Nonwoven Fabrics

In environmental and industrial settings, the filtration capability stands out among needle punched nonwoven fabrics uses. Customizable for specific particulate capture in air, water, and oil filtration, these materials are fundamental to maintaining environmental safety and industrial efficiency, showcasing versatile needle punched nonwoven fabrics uses.

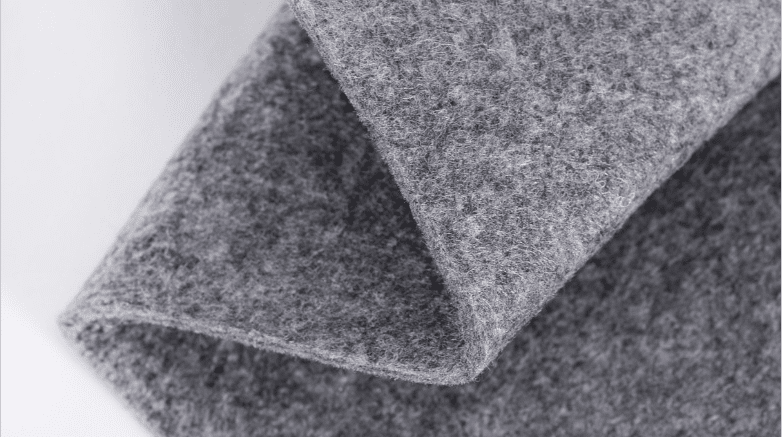

Needle Punched Nonwoven Fabrics Uses in Home and Agricultural Settings

Home Decor and Agricultural Applications

Expanding further on needle punched nonwoven fabrics uses, these materials are integral to both home decor and agriculture. They provide the base for durable carpets and upholstery in homes and manage weed control and frost protection in agricultural settings. The eco-friendly and sustainable aspects of these needle punched nonwoven fabrics uses support environmentally conscious practices in agriculture and consumer products.

Broad-Spectrum Utility and Protective Applications

Industrial and Protective Clothing Needle Punched Nonwoven Fabrics Uses

In industrial environments and protective clothing, the strength and resilience of these fabrics are crucial. Needle punched nonwoven fabrics uses here include oil absorption, soundproofing, and the creation of robust protective gear. These needle punched nonwoven fabrics uses demonstrate the material’s broad-spectrum utility across various challenging conditions.

In conclusion, needle punched nonwoven fabrics uses span a wide range of industries and applications, from infrastructure and automotive to environmental safety and home decor. The repeated emphasis on “needle punched nonwoven fabrics uses” throughout this discussion underlines their importance and versatility in numerous sectors, ensuring that their value is well recognized and appreciated.