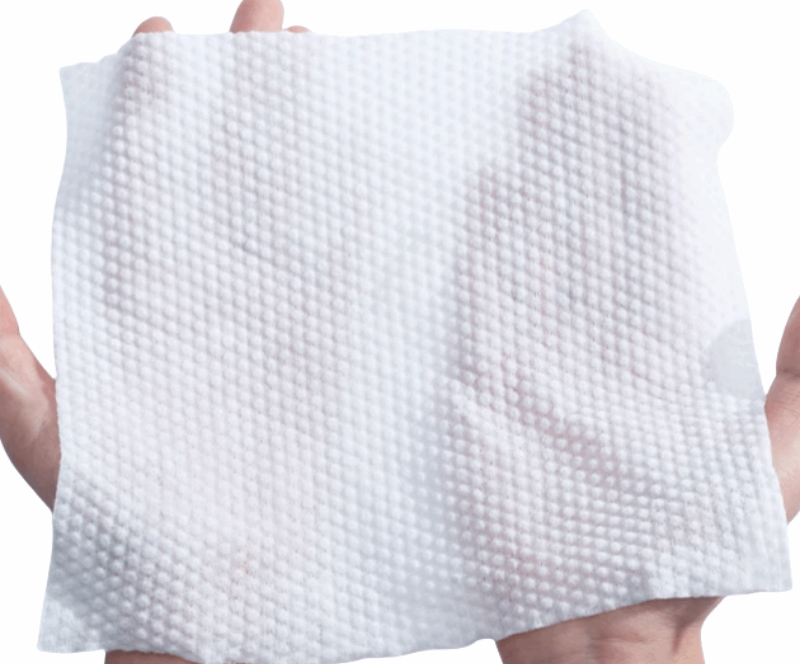

Spunlace nonwoven fabric, also known as hydroentangled nonwoven fabric, is currently primarily used in medical and healthcare products, light industry production, the electronics industry, and environmental protection sectors. It plays a positive role in promoting the development of traditional synthetic fibers and differentiated fibers by 2025.

Spunlace nonwoven fabric is an important raw material for medical masks, medical protective clothing, medical dressing gauze, surgical gowns, and artificial leather base fabrics. How to ensure the quality of spunlace nonwoven fabric through testing is a concern for relevant manufacturers.

The following four types of spunlace nonwoven fabric testing methods are provided for reference.

1. Composite spunlace nonwoven fabric testing

Composite spunlace nonwoven fabrics are primarily categorized into two types: standard and functional composite spunlace nonwoven fabrics.

Among these, functional composite spunlace nonwoven fabrics are primarily used for specialized applications such as water repellency and flame resistance. While the external quality inspection items for both types of composite spunlace nonwoven fabrics are identical, the internal quality inspection items differ slightly. The specific requirements are as follows:

- Internal quality inspection items for standard composite spunlace nonwoven fabric: deviation rate of basis weight per unit area, unevenness rate of basis weight per unit area, transverse tensile strength, absorbency, colorfastness to rubbing, and width deviation;

- Internal quality inspection items for functional composite spunlace nonwoven fabrics: unit area mass deviation rate, unit area mass unevenness rate, transverse tensile strength, colorfastness to rubbing, width deviation, water resistance performance, water absorption performance, alcohol resistance performance, and flame retardant performance;

2. Chitosan Fiber Spunlace Nonwoven Fabric Testing

Chitosan fiber spunlace nonwoven fabric testing projects are basically similar to those for sanitary spunlace nonwoven fabrics, and are also divided into three categories: intrinsic quality, extrinsic quality, and microbiological quality. Specific requirements are as follows:

- Internal quality testing items: deviation rate of basis weight per unit area, width deviation, tensile strength in longitudinal and transverse directions, deviation rate of chitosan fiber content, pH value, formaldehyde content, migratable fluorescent substances, liquid absorption capacity, antibacterial rate, heavy metal content (lead, mercury, arsenic);

- External quality testing items: fabric surface, seams, cut edges;

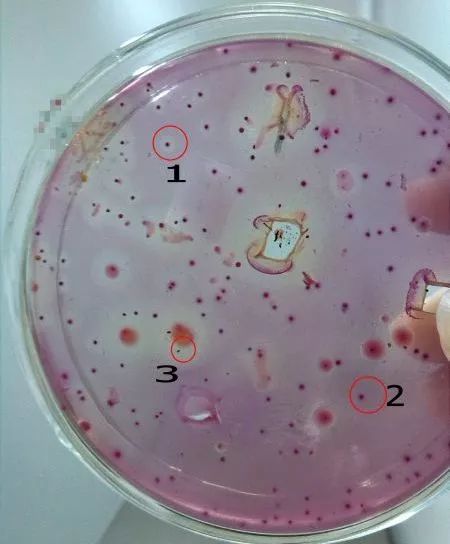

- Microbial indicator testing items: total bacterial colony count, coliform bacteria, total fungal colony count, pathogenic pyogenic bacteria, etc.

3. Hygienic spunlace nonwoven fabric testing

Hygienic spunlace nonwoven fabric testing is divided into three major categories: internal quality testing, external quality testing, and microbial indicator testing. The specific testing items are as follows:

- Internal quality testing items: unit area mass deviation rate, unit area mass coefficient of variation, thickness deviation, tensile strength, width deviation, liquid absorption capacity, pH value;

- External quality testing items: fabric surface quality defects, color difference, and imperfections;

- Microbial indicator testing items: total bacterial colony count, coliform bacteria, Staphylococcus aureus, pathogenic pus-forming bacteria, etc.

4. Insulation spunlace nonwoven fabric testing

Insulation-grade spunlace nonwoven fabric only requires testing of internal and external quality. Specific requirements are as follows:

- Internal quality testing items: mass deviation rate per unit area, thickness deviation, width deviation, limiting oxygen index, after-flame time, smoldering time, damage length, electrical strength, tensile strength, elongation at break, tear strength, relative permittivity, dielectric loss factor, thermal shrinkage rate;

- External quality testing items: The fabric surface should be uniform and flat, with no obvious creases, no torn edges, holes, oil stains, or spots, and the rolls should be neatly packaged.