Description

Parameter | Lyocell Nonwoven Specifications |

Basis Weight | 22-170gsm |

Width | 3200mm/1600mm (Custom width available) |

Material | Lyocell/Tencel/etc. |

Certifications | ISO 9001, GRS, OEKO-TEX® Standard 100,FSC |

MOQ | 500kg(<50gsm);5 tons(>50gsm) |

Patterns | Plain , Mesh , Snow, Dot Embossed , EF Pattern, T, S |

Biodegradable | YES |

Table of Contents

Lyocell + Spunlace: A Powerful Combination with Superior Benefits

When Lyocell and spunlace technology come together, the advantages are not just added — they create a “1 + 1 > 2” effect:

✨ Ultimate Comfort & Safety

Exceptionally soft, breathable, highly absorbent, and free from chemical additives. This makes Lyocell Spunlace Nonwoven the preferred choice for:

Premium beauty care (makeup remover pads, facial mask substrates)

Mother & baby products (dry/wet wipes, baby bibs)

Medical & hygiene use (advanced dressings, gauze alternatives)

💧 Outstanding Cleaning & Wiping Performance

With excellent absorbency, high tensile strength, and low linting, it is ideal for:

High-end electronic cleaning wipes

Optical instrument wipes

Luxury product care cloths

🌍 Eco-Friendly & Sustainable Brand Image

From raw material sourcing to production and disposal, the entire lifecycle aligns with modern green and sustainable consumption values. Using this material helps brands strengthen their eco-friendly and social responsibility image.

💪 High Strength & Durability

Compared with conventional cotton spunlace, Lyocell spunlace offers superior strength, better resistance to repeated wiping and wet use, and longer durability.

🌟 Premium Look & Feel

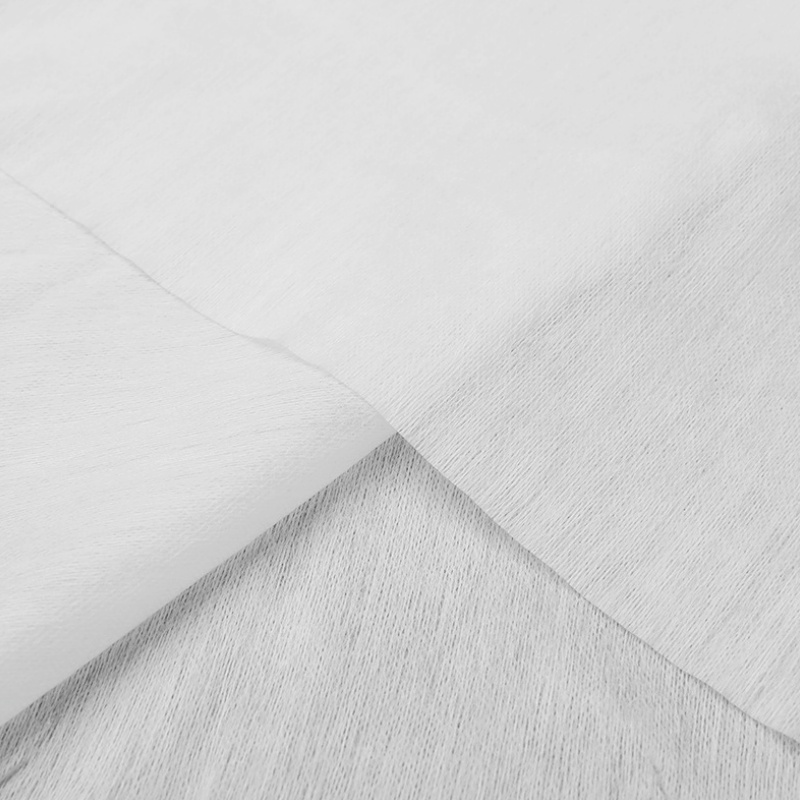

Smooth surface with a natural luster, delivering a more luxurious appearance to finished products.

Comparison Table: Lyocell Nonwoven vs. Common Nonwovens

| Property | Lyocell (Tencel) Spunlace Nonwoven | Conventional (e.g., PP/PET) Nonwoven | Cotton Spunlace Nonwoven |

| Hand Feel | Extremely soft, silky, smooth | Stiff, paper-like feel | Soft, but can be somewhat coarse |

| Absorbency | Excellent | Poor (often requires hydrophilic treatment) | Good |

| Strength | Very High (maintains strength when wet) | High when dry, loses integrity when wet | Significant loss of strength when wet |

| Environmental Impact | Best (Fully biodegradable, sustainable source) | Poor (Petroleum-based, not biodegradable) | Good (Biodegradable) |

| Composition | Natural fibers, no chemical binders | Synthetic fibers, may contain binders | Natural fibers, no chemical binders |

| Cost | High | Low | Medium |

| Primary Applications | Premium wipes, cosmetics, medical | Bags, packaging, agriculture | Standard wipes, medical dressings |

Lyocell Nonwoven Pattern for Choice

Plain pattern: smooth surface, suitable for subsequent coating or laminating.

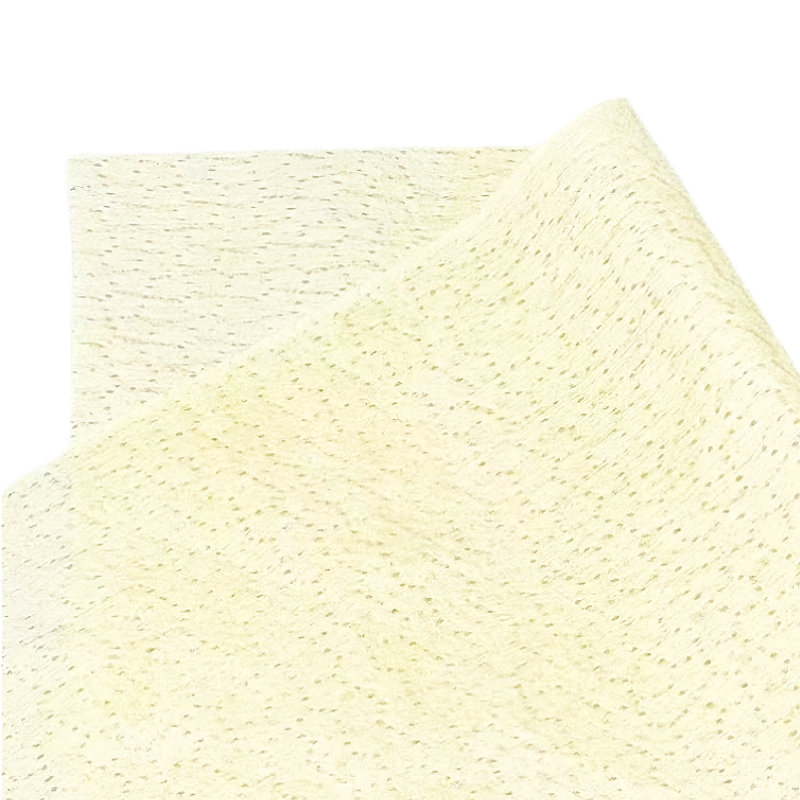

Mesh: enhanced air permeability, fast penetration of liquids.

Snow (patented pattern) : Enhance the liquid infusion, help the uniform distribution and absorption of the beauty solution, enhance the fit, and aesthetics.

Dot Embossed: Enhance surface friction and cleaning effect.

T Patterm: strong tensile strength, not easy to deform, unique texture design.

EF Pattern: increase the elasticity and strength of the fabric.

S Pattern: increase the flexibility and comfort of the fabric.

Packaging Display

Thickened packaging, moisture and dirt resistant. The thickened paper tube is not deformed. Protect the spunlace nonwoven fabric after sea transportation, perfectly to the destination point

Factory Video and Photos

Dust-free workshop, international ISO 9001 production standards, intelligent stain detection

Manufacturer Brief Introduction

Our factory is located in Changshu, Jiangsu Province, China, established in 1993, covers an area of 28,000 square meters, 146 employees, 3 spunlace production lines, annual output of 5,000 tons of spunlace non woven fabrics, supplied to several well-known international companies and Chinese head enterprises with very competitive quality and price & offers a wide range of functional and environmentally friendly spunlace non woven material customization.

Certification & Compliance

WE have ISO 9001, OEKO-TEX® Standard 100,FSC,GRS,SGS etc. to ensure the quality of our products and international export compliance.

Schedule a Factory Inspection

- Located in Changshu Industrial Park, Jiangsu, China

- Support customer on-site factory inspection (3 days in advance by appointment)

- 30 years experience in nonwoven material production

- R&D many differentiated functional materials, find the most suitable nonwoven material for your products.

Reviews

There are no reviews yet.