Description

Parameter | Specifications |

Basis Weight | 120-1500gsm |

Width | ≤3200mm (Custom slitting & film cutting) |

Color | Black/Grey/Beige + RAL/Pantone Customization |

Material | Polyester, PET, PP, PLA etc. |

Roll Length | 100-500m (Customized) |

Certifications | IATF 16949, ISO 9001, GRS, BSCI etc |

Process | Needle Felting, Pilling, Printing, Gluing, Laminating, embossed |

Table of Contents

Headliner & Car Carpet Needlepunched Nonwoven Fabric

A variety of differentiated automotive nonwoven in rolls/sheets for car headliner fabric, car carpet fabric, parcel shelf. etc

Car Interior Fabric Application

Note:Supply of automotive Headliner fabric & Car Carpet fabric rolls/sheets without finished parts

Factory Photos

Car Carpet fabric: Needle felting 3.6 metres wide 4 lines, 4 pile lines; 1 stenter line; 2 film lines; 1 vertical cutting line; 1 cutting line.

Car headliner fabric : 1 needle punching 3.6 metres wide high-speed line; 1 spray adhesive printing line; 1 cutting sheet point break line.

2 sets of press machine.

Manufacturer Brief Introduction

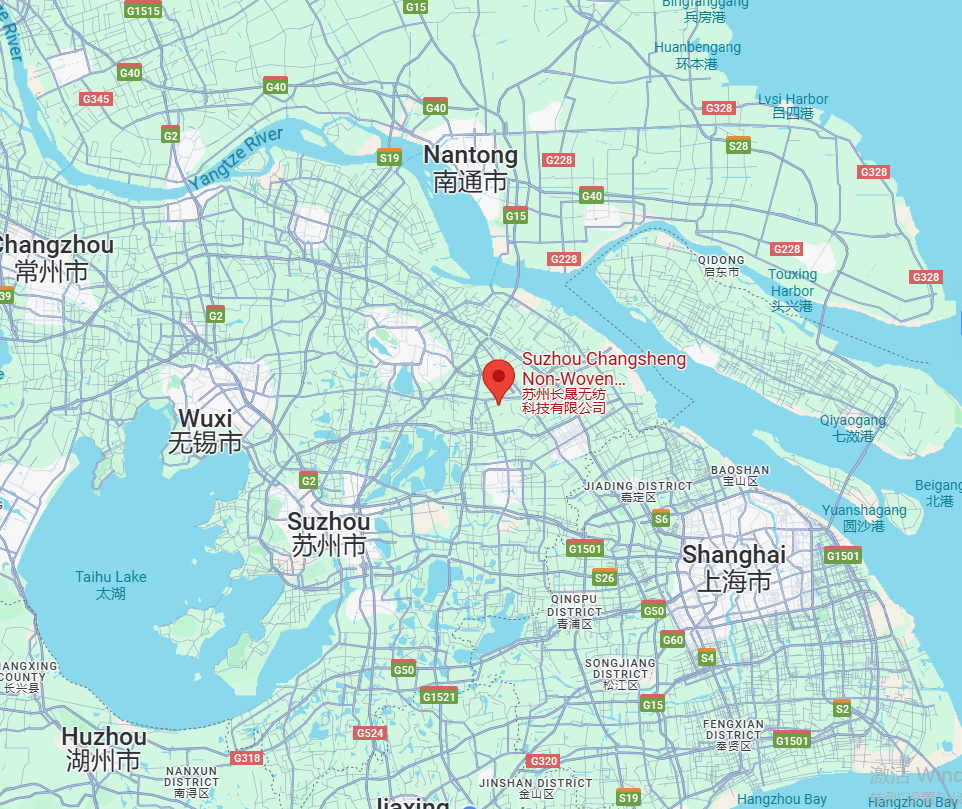

Our factory is located in Changshu, Jiangsu Province, China, established in 1993, covers an area of 28,000 square meters, has 146 employees, and 6 needle punching nonwoven production lines. We are the second-tier supplier for many world-renowned automobile companies with very competitive quality and price for Headliner fabric & Car Carpet fabric.

Schedule a Factory Inspection

- Located in Changshu Industrial Park, Jiangsu, China

- Support customer on-site factory inspection (3 days in advance by appointment)

- 30 years experience in automatic nonwoven production

- Tier 2 supplier for global top 5 automotive brands

Factory Inspection Photos

FAQ

Most frequent questions and answers

A: We use a variety of materials including Recycled Polyester, PET, PP and PLA for headliner fabric & car Carpet fabric . All materials are comply with international standards.

“A: RAL/Pantone Custom Colour Lead Time:Standard colour card selection: 25 days New colour match development: 35 days (including colour fastness pre-test)”

“A: Moisture-resistant PE film + reinforced paper core that meets the automotive industry’s ISTA 3A transportation test standards.”

“A: Our recycled polyester passes: Characteristic viscosity control: 0.80-0.85 dl/g Melting point consistency: 250-260°C Ensuring the same processing stability as virgin material.”

“A: Yes, we provide free samples for testing and evaluation, but you need to bear the delivery fee. Custom sample requests may incur a nominal fee.”

“A: Yes, we welcome factory audits and are located in Jiangsu, China. Please contact us to schedule a visit.”

Reviews

There are no reviews yet.