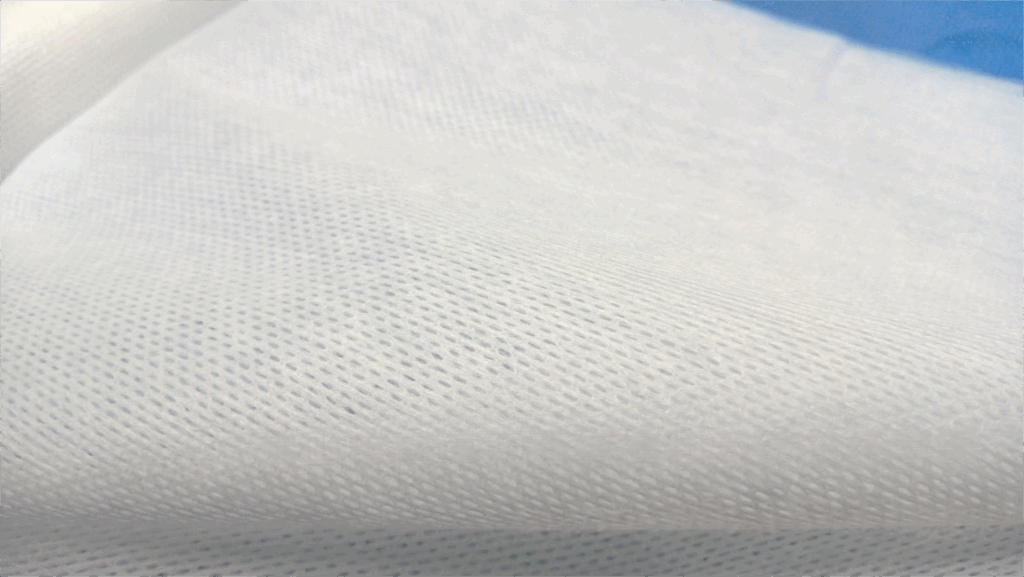

Defining Nonwoven Fabric: Beyond Traditional Textiles

Nonwoven fabric (Non Woven Fabric) is engineered by bonding fibers directionally or randomly through physical/chemical methods – not by weaving yarns. When you examine interlining in clothing, you’ll find no thread ends to pull!

Core Characteristics

✓ No warp/weft threads – Easy cutting & sewing

✓ Rapid production – 3x faster than woven textiles

✓ Cost-effective – 40-60% lower material costs

✓ Limitations: Lower durability, non-washable, prone to splitting

Industry Insight: Modern R&D focuses on anti-splitting tech for critical applications.

The 7 Classifications of Nonwoven Fabric

(Based on Production Processes)

1. Hydroentangled (Spunlace) Nonwoven

Process: High-pressure water jets entangle fiber webs.

Key Traits:

- Zero chemical additives (skin-friendly)

- Superior softness & drapability

- High absorbency (500-800% liquid retention)

- Medical-grade sterility

Applications:

◼ Medical: Surgical gowns, wound dressings

◼ Hygiene: Spunlace non woven wipes, facial masks

◼ Industrial: Precision cleaning cloths

Pro Tip: Partner with an ISO-certified spunlace fabric manufacturer for FDA-compliant medical textiles.

2. Thermally Bonded Nonwoven

Process: Heat-activated adhesives fuse fiber webs.

Key Traits:

- Smooth (area bonding) or bulky (point bonding) surface

- High production speed (250+ m/min)

Applications: Diaper liners, medical tapes, mask layers

3. Airlaid Pulp Nonwoven

Process: Wood pulp fibers air-deposited onto mesh.

Key Traits:

- Ultra-fluffy texture

- Exceptional liquid absorption

- Dust-free structure

Applications: High-end hygiene products (pads, wipes)

4. Wet-Laid Nonwoven

Process: Fiber slurry formed in water medium (paper-making technique).

Key Traits:

- Uniform fiber distribution

- High-speed production (400m/min)

- Water-intensive process

Applications: Tea bags, industrial filters, wallpaper

5. Spunbond Nonwoven

Process: Extruded polymer filaments self-bond into webs.

Key Traits:

- Excellent tensile strength

- UV/chemical resistance

- Customizable filament thickness

Applications: Geotextiles, crop covers, furniture backing

6. Meltblown Nonwoven

Process: Superheated polymers blown into microfibers (<5μm).

Key Traits:

- Ultra-fine fiber matrix

- Superior filtration efficiency

- Low web strength

Applications: N95 masks, battery separators, oil sorbents

7. Needle-Punched Nonwoven

Process: Barbed needles mechanically interlock fibers.

Key Traits:

- 3D structural integrity

- Enhanced porosity

- Customizable density

Applications: Automotive insulation, carpet underlay, synthetic leather

Critical Selection Guidelines

| Type | Best For | Avoid When |

|---|---|---|

| Spunlace | Medical/skin-contact products | Low-budget projects |

| Meltblown | Filtration systems | High-strength needs |

| Spunbond | Outdoor/industrial uses | Softness-critical apps |

✳️ Expert Note: For premium spunlace non woven solutions, audit your spunlace fabric manufacturer‘s:

- Hydroentanglement pressure (≥500 bar)

- Fiber purity controls

- Medical-grade certification

Global Market Trends (2023)

- Spunlace dominance: 38% medical textiles market share

- Sustainability shift: Biodegradable PLA fiber demand ↑ 200%

- Tech innovation: AI-driven defect detection in needle-punch lines