Many materials in automotive interiors are made of non-woven fabrics, such as headliner fabric, floor mats, and interior trim panels. So, what are the key requirements for non-woven fabrics used in automotive interiors? Below, we summarize four main points for your understanding.

1. Breathability & Moisture Permeability

Needle-punched non-woven fabrics are generally used in mid-to-low-end vehicles, typically demarcated by models like the Camry. Needle-punched and stitch-bonded non-wovens are common in mid-to-low-range cars, while high-end vehicles often use woven fabrics. During headliner molding, spunbond non-wovens may also be added for reinforcement.

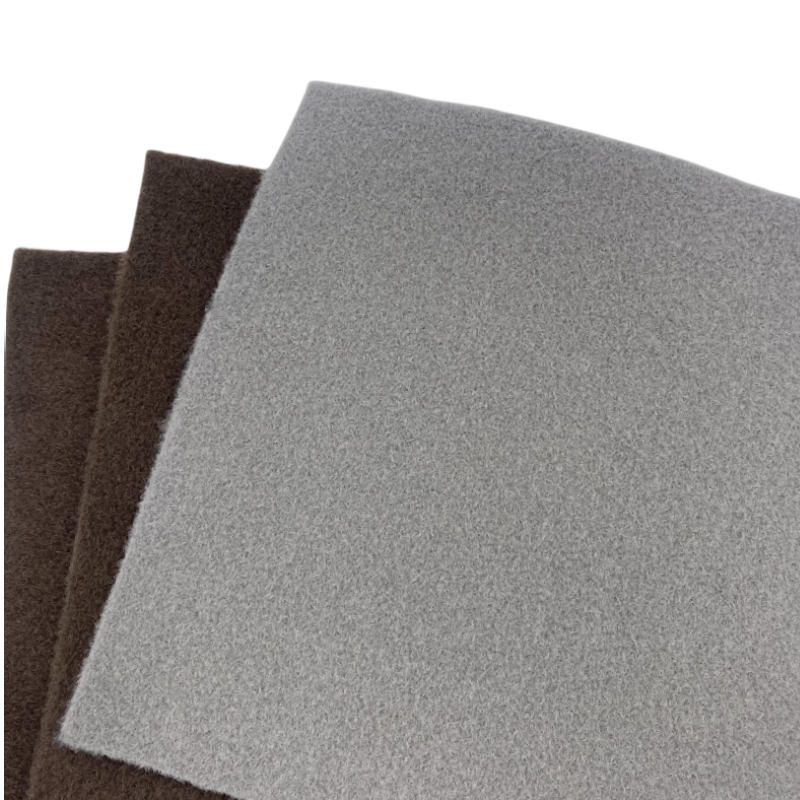

There are two main types: non-woven and knitted fabrics. Non-wovens can be further categorized into:

- Needle-punched – Made of polyester, providing a fuzzy texture; cost-effective, commonly used in compact cars and vans.

- Stitch-bonded (e.g., Malivlies stitch-bonded fabric) – Polyester-based with a loop structure resembling warp-knitted fabric, offering good thickness-direction elasticity.

Higher-end models are increasingly adopting yarnless stitch-bonded headliners, which combine durability with lightweight performance.

2. UV & Light Resistance

Automotive textiles must exhibit excellent lightfastness and UV resistance. Extreme temperature cycles can cause fading and material degradation, shortening lifespan and compromising aesthetics.

In extreme climates, cabin temperatures can reach 130°C (266°F) due to sunlight exposure. Modern vehicles feature larger glass surfaces for natural light and weight reduction, intensifying the impact of UV radiation on interior materials.

3. Fogging Resistance

Pile fabrics with large fiber surface areas are prone to fogging, exacerbated by chemical residues from dyeing and finishing processes. This issue must be strictly controlled.

Fogging occurs when volatile organic compounds (VOCs) evaporate from materials (e.g., adhesives, coatings) and condense on windows, forming a haze that:

- Obstructs driver visibility.

- Risks passenger health if inhaled.

Thus, automotive interior materials must undergo anti-fogging treatments and prolonged heat setting to minimize VOC emissions.

4. Abrasion Resistance

Common testing methods include Martindale abrasion and Taber abrasion tests. Seat fabrics require high abrasion resistance to:

- Prevent pilling and snagging.

- Maintain appearance over at least 2 years of use (often exceeding 10 years).

This property is critical for seat covers and steering wheel fabrics.

5. Flame Retardancy

Automotive textiles must meet stringent flame resistance standards, typically evaluated via horizontal burn tests. Key considerations:

- Materials should self-extinguish to delay fire spread.

- Fiber composition (e.g., polyester, treated fabrics) affects combustion behavior.

Flame-retardant non-wovens ensure passenger safety by providing escape time and reducing fire hazards.